BHU-SPANNER

Specifically designed for our adjustable upper control arms, these durable spanners provide an exact fit and ease of use. Keep your vehicle's alignment in check and maintain optimal handling with this essential spare part.

Two spanners are provided with each set of Blackhawk Ultimate Upper Control Arms, however, should these become damaged or lost, replacements are available.

DUE FOR RELEASE IN 2024!

Introducing the Revolutionary Blackhawk4x4 Adjustable Upper Control Arms

BHU3091A

Blackhawk4x4 has a long history of pioneering wheel alignment correction for lifted 4x4s. We've stood the test of time and continue to lead the way, with our relentless focus on design and manufacturing of industry-leading, fixed position Upper Control Arms (UCA’s).

But we don't stop there. As trailblazers in the field, we strive to respond to market needs and trends. Recognizing the growing need for adjustable UCAs that allow users the freedom to customise settings to their specific needs, we embarked on a new journey. We are excited to introduce the Blackhawk4x4 ULTIMATE UCA’s - the first ever street legal, on-car adjustable and forged Upper Control Arms.

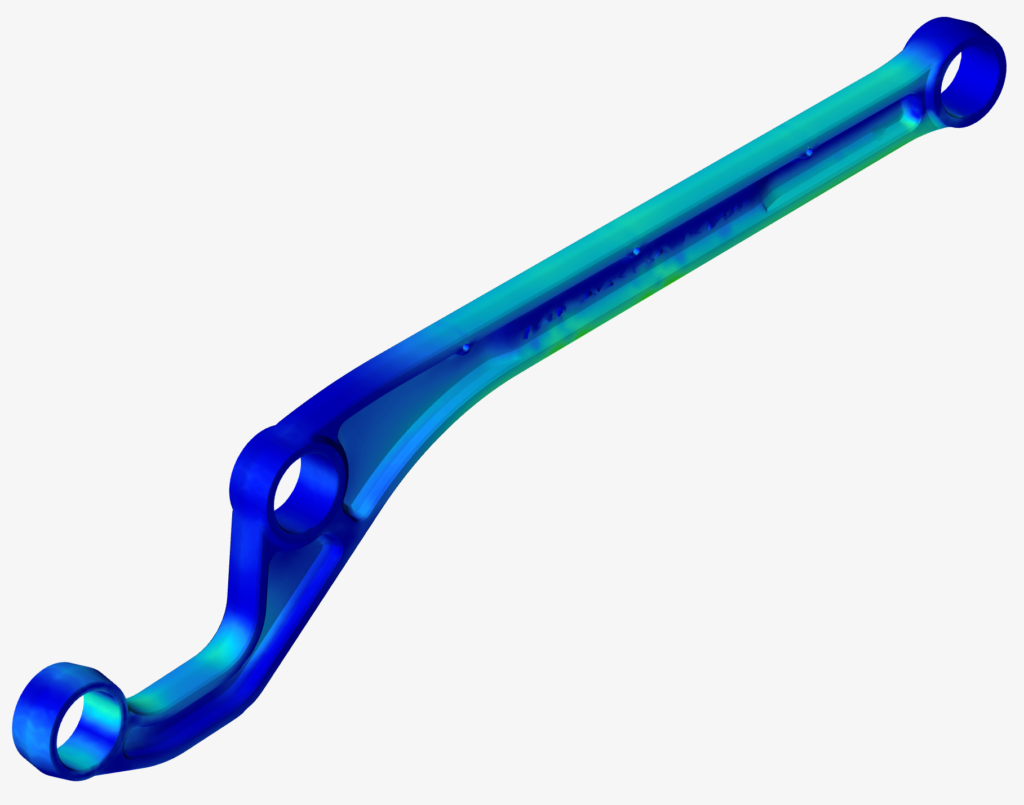

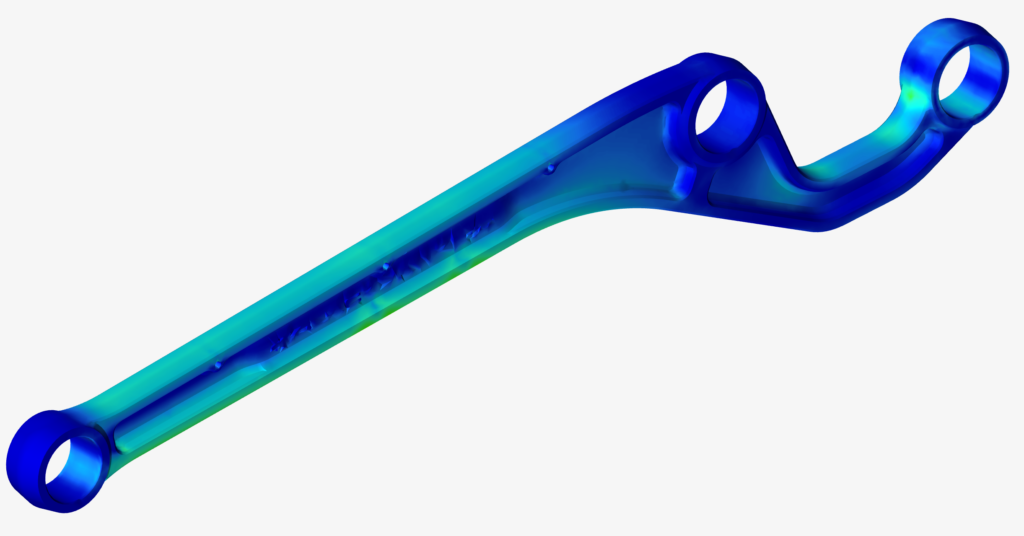

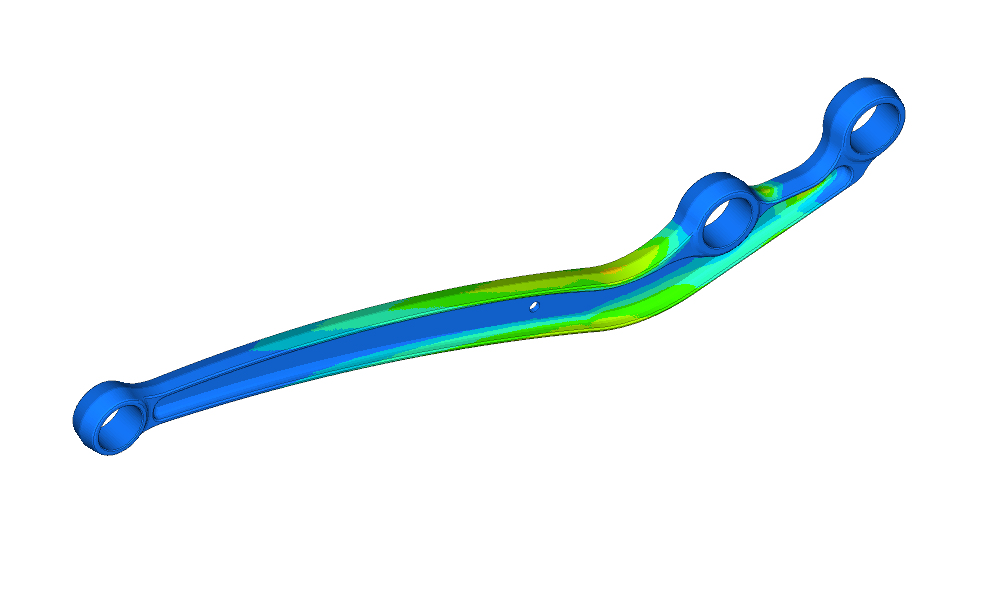

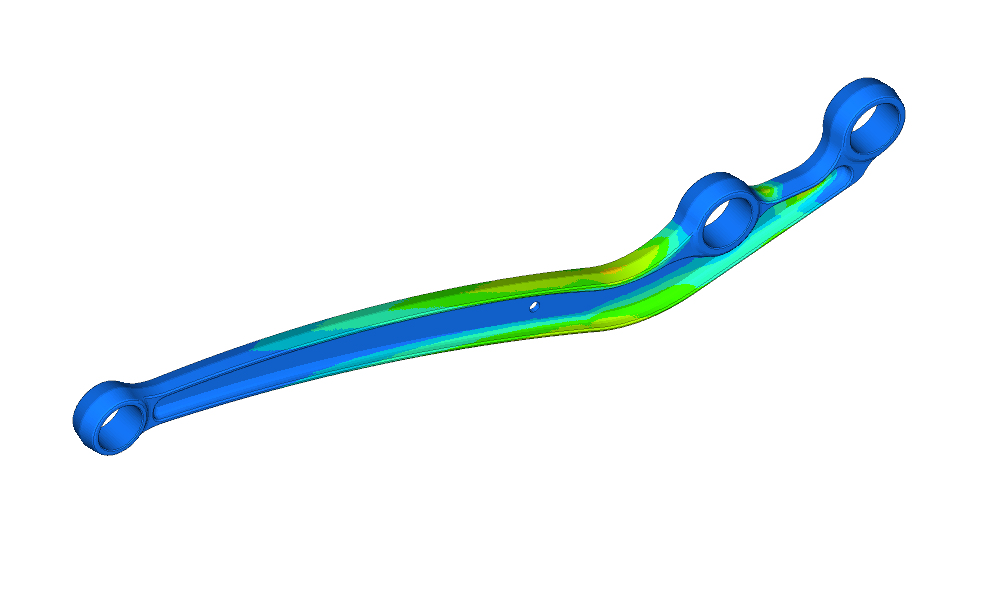

Our latest offering results from years of tireless effort by our expert team of mechanical engineers, who have worked closely with field experts such as metallurgists, VASS Engineers, and VIC Roads signatories. Utilising state-of-the-art Computer-Aided Engineering (CAD) and Finite Element Analysis (FEA) and validating our designs through rigorous physical testing in Melbourne-based NATA testing facilities, we’ve forged a product that combines the best of technology and materials for the ULTIMATE solution.

Blackhawk4x4 Adjustable UCA’s - Unleashing the Power of Precision Control

Our range of Adjustable UCA’s pack an array of superior features that make them an invaluable addition to any 4x4. They are designed with:

- A main frame forged from 6083 aluminium for durability.

- Forged 4140 bush apertures that ensure a solid and firm fit.

- Billet machined 4140 on-vehicle adjusters that allow on-the-go customisation.

- Our unique, patent-pending, dual locking proprietary nut system for added security.

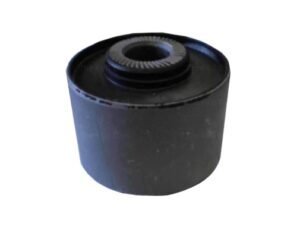

- Rubber bushings of OE spec that offer excellent vibration isolation.

- The robust and serviceable ROADSAFE high articulation, greaseable ball joint that provides a whopping 80 degrees of articulation.

- NATA certified ADR compliance for assurance of safety and reliability.

- FEA tested for ADR compliance, further reaffirming our commitment to quality and safety.

The Blackhawk4x4 ULTIMATE UCA’s provide unmatched adjustability on-car, giving OE specifications and even better for lifts from 30mm to 75mm - guaranteed, with even higher capabilities in many applications. The ball joint in the ULTIMATE UCA’s, a new design that offers 80 degrees of articulation, equals the strength of an OEM ball joint and is manufactured from high-strength 4140 chromium molybdenum (chromoly) steel.

We also provide detailed fitting instructions online, allowing users to make appropriate adjustments based on their vehicle lift and desired alignment outcome.

The Blackhawk4x4 ULTIMATE UCA’s are indeed a product by 4wders for 4wders who accept nothing less than the best. It's time to revolutionise your 4x4 experience. Let our Adjustable UCA's redefine the standards of control and performance for your vehicle. Embrace the Blackhawk4x4 difference today.

Introducing the Revolutionary Blackhawk4x4 Adjustable Upper Control Arms

BHU5251P

Blackhawk4x4 has a long history of pioneering wheel alignment correction for lifted 4x4s. We've stood the test of time and continue to lead the way, with our relentless focus on design and manufacturing of industry-leading, fixed position Upper Control Arms (UCA’s).

But we don't stop there. As trailblazers in the field, we strive to respond to market needs and trends. Recognizing the growing need for adjustable UCAs that allow users the freedom to customise settings to their specific needs, we embarked on a new journey. We are excited to introduce the Blackhawk4x4 ULTIMATE UCA’s - the first ever street legal, on-car adjustable and forged Upper Control Arms.

Our latest offering results from years of tireless effort by our expert team of mechanical engineers, who have worked closely with field experts such as metallurgists, VASS Engineers, and VIC Roads signatories. Utilising state-of-the-art Computer-Aided Engineering (CAD) and Finite Element Analysis (FEA) and validating our designs through rigorous physical testing in Melbourne-based NATA testing facilities, we’ve forged a product that combines the best of technology and materials for the ULTIMATE solution.

Blackhawk4x4 Adjustable UCA’s - Unleashing the Power of Precision Control

Our range of Adjustable UCA’s pack an array of superior features that make them an invaluable addition to any 4x4. They are designed with:

- A main frame forged from 6083 aluminium for durability.

- Forged 4140 bush apertures that ensure a solid and firm fit.

- Billet machined 4140 on-vehicle adjusters that allow on-the-go customisation.

- Our unique, patent-pending, dual locking proprietary nut system for added security.

- Rubber bushings of OE spec that offer excellent vibration isolation.

- The robust and serviceable ROADSAFE high articulation, greaseable ball joint that provides a whopping 80 degrees of articulation.

- NATA certified ADR compliance for assurance of safety and reliability.

- FEA tested for ADR compliance, further reaffirming our commitment to quality and safety.

The Blackhawk4x4 ULTIMATE UCA’s provide unmatched adjustability on-car, giving OE specifications and even better for lifts from 30mm to 75mm - guaranteed, with even higher capabilities in many applications. The ball joint in the ULTIMATE UCA’s, a new design that offers 80 degrees of articulation, equals the strength of an OEM ball joint and is manufactured from high-strength 4140 chromium molybdenum (chromoly) steel.

We also provide detailed fitting instructions online, allowing users to make appropriate adjustments based on their vehicle lift and desired alignment outcome.

The Blackhawk4x4 ULTIMATE UCA’s are indeed a product by 4wders for 4wders who accept nothing less than the best. It's time to revolutionise your 4x4 experience. Let our Adjustable UCA's redefine the standards of control and performance for your vehicle. Embrace the Blackhawk4x4 difference today.

Spare Parts are available for our entire product range!

Ball Joint Part Number: BJ5251ULTE

Bushing Part Number: S0536R

DUE FOR RELEASE IN 2024!

Introducing the Revolutionary Blackhawk4x4 Adjustable Upper Control Arms

Blackhawk4x4 has a long history of pioneering wheel alignment correction for lifted 4x4s. We've stood the test of time and continue to lead the way, with our relentless focus on design and manufacturing of industry-leading, fixed position Upper Control Arms (UCA’s).

But we don't stop there. As trailblazers in the field, we strive to respond to market needs and trends. Recognizing the growing need for adjustable UCAs that allow users the freedom to customise settings to their specific needs, we embarked on a new journey. We are excited to introduce the Blackhawk4x4 ULTIMATE UCA’s - the first ever street legal, on-car adjustable and forged Upper Control Arms.

Our latest offering results from years of tireless effort by our expert team of mechanical engineers, who have worked closely with field experts such as metallurgists, VASS Engineers, and VIC Roads signatories. Utilising state-of-the-art Computer-Aided Engineering (CAD) and Finite Element Analysis (FEA) and validating our designs through rigorous physical testing in Melbourne-based NATA testing facilities, we’ve forged a product that combines the best of technology and materials for the ULTIMATE solution.

Blackhawk4x4 Adjustable UCA’s - Unleashing the Power of Precision Control

Our range of Adjustable UCA’s pack an array of superior features that make them an invaluable addition to any 4x4. They are designed with:

- A main frame forged from 6083 aluminium for durability.

- Forged 4140 bush apertures that ensure a solid and firm fit.

- Billet machined 4140 on-vehicle adjusters that allow on-the-go customisation.

- Our unique, patent-pending, dual locking proprietary nut system for added security.

- Rubber bushings of OE spec that offer excellent vibration isolation.

- The robust and serviceable ROADSAFE high articulation, greaseable ball joint that provides a whopping 80 degrees of articulation.

- NATA certified ADR compliance for assurance of safety and reliability.

- FEA tested for ADR compliance, further reaffirming our commitment to quality and safety.

The Blackhawk4x4 ULTIMATE UCA’s provide unmatched adjustability on-car, giving OE specifications and even better for lifts from 30mm to 75mm - guaranteed, with even higher capabilities in many applications. The ball joint in the ULTIMATE UCA’s, a new design that offers 80 degrees of articulation, equals the strength of an OEM ball joint and is manufactured from high-strength 4140 chromium molybdenum (chromoly) steel.

We also provide detailed fitting instructions online, allowing users to make appropriate adjustments based on their vehicle lift and desired alignment outcome.

The Blackhawk4x4 ULTIMATE UCA’s are indeed a product by 4wders for 4wders who accept nothing less than the best. It's time to revolutionise your 4x4 experience. Let our Adjustable UCA's redefine the standards of control and performance for your vehicle. Embrace the Blackhawk4x4 difference today.

Spare Parts are available for our entire product range!

Ball Joint Part Number: BJ4861ULTE

Bushing Part Number: TBA

Introducing the Revolutionary Blackhawk4x4 Adjustable Upper Control Arms

Blackhawk4x4 has a long history of pioneering wheel alignment correction for lifted 4x4s. We've stood the test of time and continue to lead the way, with our relentless focus on design and manufacturing of industry-leading, fixed position Upper Control Arms (UCA’s).

But we don't stop there. As trailblazers in the field, we strive to respond to market needs and trends. Recognizing the growing need for adjustable UCAs that allow users the freedom to customise settings to their specific needs, we embarked on a new journey. We are excited to introduce the Blackhawk4x4 ULTIMATE UCA’s - the first ever street legal, on-car adjustable and forged Upper Control Arms.

Our latest offering results from years of tireless effort by our expert team of mechanical engineers, who have worked closely with field experts such as metallurgists, VASS Engineers, and VIC Roads signatories. Utilising state-of-the-art Computer-Aided Engineering (CAD) and Finite Element Analysis (FEA) and validating our designs through rigorous physical testing in Melbourne-based NATA testing facilities, we’ve forged a product that combines the best of technology and materials for the ULTIMATE solution.

Blackhawk4x4 Adjustable UCA’s - Unleashing the Power of Precision Control

Our range of Adjustable UCA’s pack an array of superior features that make them an invaluable addition to any 4x4. They are designed with:

- A main frame forged from 6083 aluminium for durability.

- Forged 4140 bush apertures that ensure a solid and firm fit.

- Billet machined 4140 on-vehicle adjusters that allow on-the-go customisation.

- Our unique, patent-pending, dual locking proprietary nut system for added security.

- Rubber bushings of OE spec that offer excellent vibration isolation.

- The robust and serviceable ROADSAFE high articulation, greaseable ball joint that provides a whopping 80 degrees of articulation.

- NATA certified ADR compliance for assurance of safety and reliability.

- FEA tested for ADR compliance, further reaffirming our commitment to quality and safety.

The Blackhawk4x4 ULTIMATE UCA’s provide unmatched adjustability on-car, giving OE specifications and even better for lifts from 30mm to 75mm - guaranteed, with even higher capabilities in many applications. The ball joint in the ULTIMATE UCA’s, a new design that offers 80 degrees of articulation, equals the strength of an OEM ball joint and is manufactured from high-strength 4140 chromium molybdenum (chromoly) steel.

We also provide detailed fitting instructions online, allowing users to make appropriate adjustments based on their vehicle lift and desired alignment outcome.

The Blackhawk4x4 ULTIMATE UCA’s are indeed a product by 4wders for 4wders who accept nothing less than the best. It's time to revolutionise your 4x4 experience. Let our Adjustable UCA's redefine the standards of control and performance for your vehicle. Embrace the Blackhawk4x4 difference today.

Spare Parts are available for our entire product range!

Ball Joint Part Number: BJ4727ULTE

Bushing Part Number: S0541R

Introducing the Revolutionary Blackhawk4x4 Adjustable Upper Control Arms

BHU3957R

Blackhawk4x4 has a long history of pioneering wheel alignment correction for lifted 4x4s. We've stood the test of time and continue to lead the way, with our relentless focus on design and manufacturing of industry-leading, fixed position Upper Control Arms (UCA’s).

But we don't stop there. As trailblazers in the field, we strive to respond to market needs and trends. Recognizing the growing need for adjustable UCAs that allow users the freedom to customise settings to their specific needs, we embarked on a new journey. We are excited to introduce the Blackhawk4x4 ULTIMATE UCA’s - the first ever street legal, on-car adjustable and forged Upper Control Arms.

Our latest offering results from years of tireless effort by our expert team of mechanical engineers, who have worked closely with field experts such as metallurgists, VASS Engineers, and VIC Roads signatories. Utilising state-of-the-art Computer-Aided Engineering (CAD) and Finite Element Analysis (FEA) and validating our designs through rigorous physical testing in Melbourne-based NATA testing facilities, we’ve forged a product that combines the best of technology and materials for the ULTIMATE solution.

Blackhawk4x4 Adjustable UCA’s - Unleashing the Power of Precision Control

Our range of Adjustable UCA’s pack an array of superior features that make them an invaluable addition to any 4x4. They are designed with:

- A main frame forged from 6083 aluminium for durability.

- Forged 4140 bush apertures that ensure a solid and firm fit.

- Billet machined 4140 on-vehicle adjusters that allow on-the-go customisation.

- Our unique, patent-pending, dual locking proprietary nut system for added security.

- Rubber bushings of OE spec that offer excellent vibration isolation.

- The robust and serviceable ROADSAFE high articulation, greaseable ball joint that provides a whopping 80 degrees of articulation.

- NATA certified ADR compliance for assurance of safety and reliability.

- FEA tested for ADR compliance, further reaffirming our commitment to quality and safety.

The Blackhawk4x4 ULTIMATE UCA’s provide unmatched adjustability on-car, giving OE specifications and even better for lifts from 30mm to 75mm - guaranteed, with even higher capabilities in many applications. The ball joint in the ULTIMATE UCA’s, a new design that offers 80 degrees of articulation, equals the strength of an OEM ball joint and is manufactured from high-strength 4140 chromium molybdenum (chromoly) steel.

We also provide detailed fitting instructions online, allowing users to make appropriate adjustments based on their vehicle lift and desired alignment outcome.

The Blackhawk4x4 ULTIMATE UCA’s are indeed a product by 4wders for 4wders who accept nothing less than the best. It's time to revolutionise your 4x4 experience. Let our Adjustable UCA's redefine the standards of control and performance for your vehicle. Embrace the Blackhawk4x4 difference today.

Spare Parts are available for our entire product range!

Ball Joint Part Number: BJ3957ULTE

Bushing Part Number: S0527R

Introducing the Revolutionary Blackhawk4x4 Adjustable Upper Control Arms

BHU4981N

Blackhawk4x4 has a long history of pioneering wheel alignment correction for lifted 4x4s. We've stood the test of time and continue to lead the way, with our relentless focus on design and manufacturing of industry-leading, fixed position Upper Control Arms (UCA’s).

But we don't stop there. As trailblazers in the field, we strive to respond to market needs and trends. Recognizing the growing need for adjustable UCAs that allow users the freedom to customise settings to their specific needs, we embarked on a new journey. We are excited to introduce the Blackhawk4x4 ULTIMATE UCA’s - the first ever street legal, on-car adjustable and forged Upper Control Arms.

Our latest offering results from years of tireless effort by our expert team of mechanical engineers, who have worked closely with field experts such as metallurgists, VASS Engineers, and VIC Roads signatories. Utilising state-of-the-art Computer-Aided Engineering (CAD) and Finite Element Analysis (FEA) and validating our designs through rigorous physical testing in Melbourne-based NATA testing facilities, we’ve forged a product that combines the best of technology and materials for the ULTIMATE solution.

Blackhawk4x4 Adjustable UCA’s - Unleashing the Power of Precision Control

Our range of Adjustable UCA’s pack an array of superior features that make them an invaluable addition to any 4x4. They are designed with:

- A main frame forged from 6083 aluminium for durability.

- Forged 4140 bush apertures that ensure a solid and firm fit.

- Billet machined 4140 on-vehicle adjusters that allow on-the-go customisation.

- Our unique, patent-pending, dual locking proprietary nut system for added security.

- Rubber bushings of OE spec that offer excellent vibration isolation.

- The robust and serviceable ROADSAFE high articulation, greaseable ball joint that provides a whopping 80 degrees of articulation.

- NATA certified ADR compliance for assurance of safety and reliability.

- FEA tested for ADR compliance, further reaffirming our commitment to quality and safety.

The Blackhawk4x4 ULTIMATE UCA’s provide unmatched adjustability on-car, giving OE specifications and even better for lifts from 30mm to 75mm - guaranteed, with even higher capabilities in many applications. The ball joint in the ULTIMATE UCA’s, a new design that offers 80 degrees of articulation, equals the strength of an OEM ball joint and is manufactured from high-strength 4140 chromium molybdenum (chromoly) steel.

We also provide detailed fitting instructions online, allowing users to make appropriate adjustments based on their vehicle lift and desired alignment outcome.

The Blackhawk4x4 ULTIMATE UCA’s are indeed a product by 4wders for 4wders who accept nothing less than the best. It's time to revolutionise your 4x4 experience. Let our Adjustable UCA's redefine the standards of control and performance for your vehicle. Embrace the Blackhawk4x4 difference today.

Spare Parts are available for our entire product range!

Ball Joint Part Number: BJ4981ULTE

Bushing Part Number: S0538R

Introducing the Revolutionary Blackhawk4x4 Adjustable Upper Control Arms

BHU3841P

Blackhawk4x4 has a long history of pioneering wheel alignment correction for lifted 4x4s. We've stood the test of time and continue to lead the way, with our relentless focus on design and manufacturing of industry-leading, fixed position Upper Control Arms (UCA’s).

But we don't stop there. As trailblazers in the field, we strive to respond to market needs and trends. Recognizing the growing need for adjustable UCAs that allow users the freedom to customise settings to their specific needs, we embarked on a new journey. We are excited to introduce the Blackhawk4x4 ULTIMATE UCA’s - the first ever street legal, on-car adjustable and forged Upper Control Arms.

Our latest offering results from years of tireless effort by our expert team of mechanical engineers, who have worked closely with field experts such as metallurgists, VASS Engineers, and VIC Roads signatories. Utilising state-of-the-art Computer-Aided Engineering (CAD) and Finite Element Analysis (FEA) and validating our designs through rigorous physical testing in Melbourne-based NATA testing facilities, we’ve forged a product that combines the best of technology and materials for the ULTIMATE solution.

Blackhawk4x4 Adjustable UCA’s - Unleashing the Power of Precision Control

Our range of Adjustable UCA’s pack an array of superior features that make them an invaluable addition to any 4x4. They are designed with:

- A main frame forged from 6083 aluminium for durability.

- Forged 4140 bush apertures that ensure a solid and firm fit.

- Billet machined 4140 on-vehicle adjusters that allow on-the-go customisation.

- Our unique, patent-pending, dual locking proprietary nut system for added security.

- Rubber bushings of OE spec that offer excellent vibration isolation.

- The robust and serviceable ROADSAFE high articulation, greaseable ball joint that provides a whopping 80 degrees of articulation.

- NATA certified ADR compliance for assurance of safety and reliability.

- FEA tested for ADR compliance, further reaffirming our commitment to quality and safety.

The Blackhawk4x4 ULTIMATE UCA’s provide unmatched adjustability on-car, giving OE specifications and even better for lifts from 30mm to 75mm - guaranteed, with even higher capabilities in many applications. The ball joint in the ULTIMATE UCA’s, a new design that offers 80 degrees of articulation, equals the strength of an OEM ball joint and is manufactured from high-strength 4140 chromium molybdenum (chromoly) steel.

We also provide detailed fitting instructions online, allowing users to make appropriate adjustments based on their vehicle lift and desired alignment outcome.

The Blackhawk4x4 ULTIMATE UCA’s are indeed a product by 4wders for 4wders who accept nothing less than the best. It's time to revolutionise your 4x4 experience. Let our Adjustable UCA's redefine the standards of control and performance for your vehicle. Embrace the Blackhawk4x4 difference today.

Spare Parts are available for our entire product range!

Ball Joint Part Number: BJ3841ULTE

Bushing Part Number: S0525R

Introducing the Revolutionary Blackhawk4x4 Adjustable Upper Control Arms

BHU3841T

Blackhawk4x4 has a long history of pioneering wheel alignment correction for lifted 4x4s. We've stood the test of time and continue to lead the way, with our relentless focus on design and manufacturing of industry-leading, fixed position Upper Control Arms (UCA’s).

But we don't stop there. As trailblazers in the field, we strive to respond to market needs and trends. Recognizing the growing need for adjustable UCAs that allow users the freedom to customise settings to their specific needs, we embarked on a new journey. We are excited to introduce the Blackhawk4x4 ULTIMATE UCA’s - the first ever street legal, on-car adjustable and forged Upper Control Arms.

Our latest offering results from years of tireless effort by our expert team of mechanical engineers, who have worked closely with field experts such as metallurgists, VASS Engineers, and VIC Roads signatories. Utilising state-of-the-art Computer-Aided Engineering (CAD) and Finite Element Analysis (FEA) and validating our designs through rigorous physical testing in Melbourne-based NATA testing facilities, we’ve forged a product that combines the best of technology and materials for the ULTIMATE solution.

Blackhawk4x4 Adjustable UCA’s - Unleashing the Power of Precision Control

Our range of Adjustable UCA’s pack an array of superior features that make them an invaluable addition to any 4x4. They are designed with:

- A main frame forged from 6083 aluminium for durability.

- Forged 4140 bush apertures that ensure a solid and firm fit.

- Billet machined 4140 on-vehicle adjusters that allow on-the-go customisation.

- Our unique, patent-pending, dual locking proprietary nut system for added security.

- Rubber bushings of OE spec that offer excellent vibration isolation.

- The robust and serviceable ROADSAFE high articulation, greaseable ball joint that provides a whopping 80 degrees of articulation.

- NATA certified ADR compliance for assurance of safety and reliability.

- FEA tested for ADR compliance, further reaffirming our commitment to quality and safety.

The Blackhawk4x4 ULTIMATE UCA’s provide unmatched adjustability on-car, giving OE specifications and even better for lifts from 30mm to 75mm - guaranteed, with even higher capabilities in many applications. The ball joint in the ULTIMATE UCA’s, a new design that offers 80 degrees of articulation, equals the strength of an OEM ball joint and is manufactured from high-strength 4140 chromium molybdenum (chromoly) steel.

We also provide detailed fitting instructions online, allowing users to make appropriate adjustments based on their vehicle lift and desired alignment outcome.

The Blackhawk4x4 ULTIMATE UCA’s are indeed a product by 4wders for 4wders who accept nothing less than the best. It's time to revolutionise your 4x4 experience. Let our Adjustable UCA's redefine the standards of control and performance for your vehicle. Embrace the Blackhawk4x4 difference today.

Spare Parts are available for our entire product range!

Ball Joint Part Number: BJ3841ULTE

Bushing Part Number: S0526R

Introducing the Revolutionary Blackhawk4x4 Adjustable Upper Control Arms

BHU3881H

Blackhawk4x4 has a long history of pioneering wheel alignment correction for lifted 4x4s. We've stood the test of time and continue to lead the way, with our relentless focus on design and manufacturing of industry-leading, fixed position Upper Control Arms (UCA’s).

But we don't stop there. As trailblazers in the field, we strive to respond to market needs and trends. Recognizing the growing need for adjustable UCAs that allow users the freedom to customise settings to their specific needs, we embarked on a new journey. We are excited to introduce the Blackhawk4x4 ULTIMATE UCA’s - the first ever street legal, on-car adjustable and forged Upper Control Arms.

Our latest offering results from years of tireless effort by our expert team of mechanical engineers, who have worked closely with field experts such as metallurgists, VASS Engineers, and VIC Roads signatories. Utilising state-of-the-art Computer-Aided Engineering (CAD) and Finite Element Analysis (FEA) and validating our designs through rigorous physical testing in Melbourne-based NATA testing facilities, we’ve forged a product that combines the best of technology and materials for the ULTIMATE solution.

Blackhawk4x4 Adjustable UCA’s - Unleashing the Power of Precision Control

Our range of Adjustable UCA’s pack an array of superior features that make them an invaluable addition to any 4x4. They are designed with:

- A main frame forged from 6083 aluminium for durability.

- Forged 4140 bush apertures that ensure a solid and firm fit.

- Billet machined 4140 on-vehicle adjusters that allow on-the-go customisation.

- Our unique, patent-pending, dual locking proprietary nut system for added security.

- Rubber bushings of OE spec that offer excellent vibration isolation.

- The robust and serviceable ROADSAFE high articulation, greaseable ball joint that provides a whopping 80 degrees of articulation.

- NATA certified ADR compliance for assurance of safety and reliability.

- FEA tested for ADR compliance, further reaffirming our commitment to quality and safety.

The Blackhawk4x4 ULTIMATE UCA’s provide unmatched adjustability on-car, giving OE specifications and even better for lifts from 30mm to 75mm - guaranteed, with even higher capabilities in many applications. The ball joint in the ULTIMATE UCA’s, a new design that offers 80 degrees of articulation, equals the strength of an OEM ball joint and is manufactured from high-strength 4140 chromium molybdenum (chromoly) steel.

We also provide detailed fitting instructions online, allowing users to make appropriate adjustments based on their vehicle lift and desired alignment outcome.

The Blackhawk4x4 ULTIMATE UCA’s are indeed a product by 4wders for 4wders who accept nothing less than the best. It's time to revolutionise your 4x4 experience. Let our Adjustable UCA's redefine the standards of control and performance for your vehicle. Embrace the Blackhawk4x4 difference today.

Spare Parts are available for our entire product range!

Ball Joint Part Number: BJ3881ULTE

Bushing Part Number: S0525R

UCA4821N

Blackhawk 4×4 have identified a requirement for a program supplying replacement Upper control arm’s (UCA) that are fitted to a wide range of late model IFS vehicles. As a result we have developed the Blackhawk program – a product that will bolt in with marked improvements over the OE design.

The evolution of the Blackhawk UCA’s…

When a vehicle has raised suspension and this can be anything from 30mm or above, it will disrupt the vehicles relationship with factory set geometry and create issues such as…

- Reduced caster correction – causing vague steering and response

- Bump steer resulting in reduced handling – with an out of control feeling

- Clearance issues to suspension & wheels/tyres – larger wheels can hit suspension components

- Some standard vehicles can have an issue of the UCA hitting the coil on full droop,

- Strength of OE equipment in offroad scenarios –

Roadsafe 4WD have developed their UCA range of product drawing from over 30 years of experience in the manufacture & supply of chassis parts including but not limited to steering & suspension components. The Blackhawk UCA’s have been designed in conjunction with industry experts to ensure vehicle fitment is comprehensive. In this process we identified a large number of issues that can be present, resulting in a list of features we included to overcome these issues…

- Fixed Caster correction, we’ve identified the correct amount of caster correction required for lifts ranging from 30-70mm, by providing a bulk – fixed amount of caster, this offers the ability to utilise the factory adjustment to fine tune the caster required for your vehicles lift, with the UCA not being the limiting factor for increased droop relative to the other components.

- Camber change to meet OE spec, if your application requires increased camber, we can offer offset bushings to provide more camber.

- Clearance to larger aftermarket wheels & tyres – we often see larger than standard size tyres with wheel offsets having clearance issues to the OE UCA, our Blackhawk UCA’s minimise this as much as possible.

- Clearance to suspension components & chassis – a large number of OE UCA’s hit the coil or the chassis mounts on during the suspension travel limiting the amount of travel you can achieve, with revised bends and clearances identified the Blackhawk UCA’s will not contact the strut or the chassis limiting travel unless specifically designed to do so.

- Fixed position balljoint – Blackhawk UCA’s do not use an adjustable balljoint, with a fixed location balljoint we are able to offer OE specification for the ball joint itself.

- The position of the balljoint housings have been rotated to ensure the balljoint is not the limiting factor with maximum down travel. Roadsafe specifically chose a fixed ball joint for a number of reasons – in offroad applications the ball joint receives a large amount of “bump” loads, which over time can either knock an adjustable ball joint out of position leading to increased tyre wear due to a change in caster. Changing from a fixed balljoint mount reduces the structural integrity of the mount and the mounting platform of the balljoint, with any remote traveling we need to ensure strength and reliability is not compromised.

- There will never be a need to adjust or re-adjust your caster once established with the Blackhawk arms as the balljoint cannot be knocked out of position.

- Maintain OE specification ball joint & bushings – regardless of where you may go, if you need to replace a balljoint or bushing you can use genuine replacement parts or aftermarket OE specification replacement items, regardless of how remote you are at home or abroad.

- Ball joint binding – Often we see the ball joint limiting the amount of down travel because the OE ball stud hits the side of the ball joint housing, this creates a stress point on the ball stud creating an environment for potential terminal failure of the ball joint, it also limits the amount of down travel possible when used in conjunction with aftermarket suspension and longer shock lengths.

- Securing ABS lines – we incorporate tabs and mounts where practical so the OE lines can be secured discreetly where possible, reducing the potential of sticks and other debris from damaging the sensitive lines.

- Increased strength compared to the OE design – The design of the Blackhawk arms have shown with the use of FEA to be much stiffer than the OE arms, providing the driver with increased handling and response when the Blackhawk arms are fitted when compared to the OE arms, this is illustrated by the amount of deflection the FEA results have provided, with 3 times less deflection in the Blackhawk UCA’s.

Does this rigidity negatively transfer to the vehicle – No, because the Blackhawk arms use OE Rubber bushing, any NVH (Noise, Vibration and harshness) is absorbed in the rubber bushings before it makes it way to the chassis, you may find an increase in wear in the bushings which is directly related to how you drive the vehicle, the bushings are a consumable component of any vehicle, however you should expect years of trouble free service before the need to replace the bushings.

- Heavy Duty Long life Balljoints – Roadsafe 4wd specially redesigned the OE balljoint into a heavy duty application, due to the nature of the application the 4wding community require a serviceable component, so we have a balljoint that is manufactured in the “hard to hard” style with a locating nylon disc that the ball stud terminates against, grease is pumped into the assembly through the top keeping everything lubricated and keeping any potential contaminants out of the boot region. The ball studs and seat area of the housing are all heat treated forming a hardened surface with the purpose of long life and limited wear.

- Dust Cap – Blackhawk arms that utilise a press in balljoint feature a machined alloy dust cap which is anodized black with engraved Blackhawk logo to deter corrosion etc, as a result creating a sealed housing to remove the balljoint from the elements such as water, dust & mud ensuring they are in the best possible environment.

- Finish – All arms are sand blasted upon completion and E coated black for a durable discreet finish, E coating is the same process the vehicles manufacturer used for the original equipment you are replacing.

OEM & Blackhawk Upper control arm samples have been computer modeled and subsequently FEA tested with static and bump/lateral load tests, these results have been reviewed and certified by VASS Engineers locally who unequivocally confirm the design and materials chosen to manufacture the Blackhawk arms by long term suspension manufacturer Roadsafe Automotive products, and that they are of sound design and furthermore exceed the original equipment by design in strength and functionality.

A key feature identified by the FEA testing was the amount of deflection seen between the OE component and the Blackhawk UCA, with the Blackhawk arms being 3 times stiffer than the original equipment, resulting in significant increased handling and feel of your vehicle as the suspension cycles.

The manufacturing process is controlled by Roadsafe with a range of Quality Assurance procedures in place, some of these include…

- Welding specifications, Material & procedure

- Material selection

- Manufacturing jigs inspected for conformity regularly

- Random post manufacturing QC checks

- ISO/TS16949:2009

- IATF number 0224504 – Manufacture of steering and suspension parts

Based on years of experience in manufacturing a large volume of suspension components, Roadsafe is able to ensure the manufacturing process is of standard delivering a high quality component to market.

Spare Parts are available for our entire product range!

Ball Joint Part Number: BJ4821HD

Bushing Part Number: S0538R

Ball Joint Cap Part Number: UCABHCAP4

Blackhawk 4×4 have identified a requirement for a program supplying replacement Upper control arm’s (UCA) that are fitted to a wide range of late model IFS vehicles. As a result we have developed the Blackhawk program – a product that will bolt in with marked improvements over the OE design.

The evolution of the Blackhawk UCA’s…

UCA3841F

When a vehicle has raised suspension and this can be anything from 30mm or above, it will disrupt the vehicles relationship with factory set geometry and create issues such as…

- Reduced caster correction – causing vague steering and response

- Bump steer resulting in reduced handling – with an out of control feeling

- Clearance issues to suspension & wheels/tyres – larger wheels can hit suspension components

- Some standard vehicles can have an issue of the UCA hitting the coil on full droop,

- Strength of OE equipment in offroad scenarios –

Roadsafe 4WD have developed their UCA range of product drawing from over 30 years of experience in the manufacture & supply of chassis parts including but not limited to steering & suspension components. The Blackhawk UCA’s have been designed in conjunction with industry experts to ensure vehicle fitment is comprehensive. In this process we identified a large number of issues that can be present, resulting in a list of features we included to overcome these issues…

- Fixed Caster correction, we’ve identified the correct amount of caster correction required for lifts ranging from 30-70mm, by providing a bulk – fixed amount of caster, this offers the ability to utilise the factory adjustment to fine tune the caster required for your vehicles lift, with the UCA not being the limiting factor for increased droop relative to the other components.

- Camber change to meet OE spec, if your application requires increased camber, we can offer offset bushings to provide more camber.

- Clearance to larger aftermarket wheels & tyres – we often see larger than standard size tyres with wheel offsets having clearance issues to the OE UCA, our Blackhawk UCA’s minimise this as much as possible.

- Clearance to suspension components & chassis – a large number of OE UCA’s hit the coil or the chassis mounts on during the suspension travel limiting the amount of travel you can achieve, with revised bends and clearances identified the Blackhawk UCA’s will not contact the strut or the chassis limiting travel unless specifically designed to do so.

- Fixed position balljoint – Blackhawk UCA’s do not use an adjustable balljoint, with a fixed location balljoint we are able to offer OE specification for the ball joint itself.

- The position of the balljoint housings have been rotated to ensure the balljoint is not the limiting factor with maximum down travel. Roadsafe specifically chose a fixed ball joint for a number of reasons – in offroad applications the ball joint receives a large amount of “bump” loads, which over time can either knock an adjustable ball joint out of position leading to increased tyre wear due to a change in caster. Changing from a fixed balljoint mount reduces the structural integrity of the mount and the mounting platform of the balljoint, with any remote traveling we need to ensure strength and reliability is not compromised.

- There will never be a need to adjust or re-adjust your caster once established with the Blackhawk arms as the balljoint cannot be knocked out of position.

- Maintain OE specification ball joint & bushings – regardless of where you may go, if you need to replace a balljoint or bushing you can use genuine replacement parts or aftermarket OE specification replacement items, regardless of how remote you are at home or abroad.

- Ball joint binding – Often we see the ball joint limiting the amount of down travel because the OE ball stud hits the side of the ball joint housing, this creates a stress point on the ball stud creating an environment for potential terminal failure of the ball joint, it also limits the amount of down travel possible when used in conjunction with aftermarket suspension and longer shock lengths.

- Securing ABS lines – we incorporate tabs and mounts where practical so the OE lines can be secured discreetly where possible, reducing the potential of sticks and other debris from damaging the sensitive lines.

- Increased strength compared to the OE design – The design of the Blackhawk arms have shown with the use of FEA to be much stiffer than the OE arms, providing the driver with increased handling and response when the Blackhawk arms are fitted when compared to the OE arms, this is illustrated by the amount of deflection the FEA results have provided, with 3 times less deflection in the Blackhawk UCA’s.

Does this rigidity negatively transfer to the vehicle – No, because the Blackhawk arms use OE Rubber bushing, any NVH (Noise, Vibration and harshness) is absorbed in the rubber bushings before it makes it way to the chassis, you may find an increase in wear in the bushings which is directly related to how you drive the vehicle, the bushings are a consumable component of any vehicle, however you should expect years of trouble free service before the need to replace the bushings.

- Heavy Duty Long life Balljoints – Roadsafe 4wd specially redesigned the OE balljoint into a heavy duty application, due to the nature of the application the 4wding community require a serviceable component, so we have a balljoint that is manufactured in the “hard to hard” style with a locating nylon disc that the ball stud terminates against, grease is pumped into the assembly through the top keeping everything lubricated and keeping any potential contaminants out of the boot region. The ball studs and seat area of the housing are all heat treated forming a hardened surface with the purpose of long life and limited wear.

- Dust Cap – Blackhawk arms that utilise a press in balljoint feature a machined alloy dust cap which is anodized black with engraved Blackhawk logo to deter corrosion etc, as a result creating a sealed housing to remove the balljoint from the elements such as water, dust & mud ensuring they are in the best possible environment.

- Finish – All arms are sand blasted upon completion and E coated black for a durable discreet finish, E coating is the same process the vehicles manufacturer used for the original equipment you are replacing.

OEM & Blackhawk Upper control arm samples have been computer modelled and subsequently FEA tested with static and bump/lateral load tests, these results have been reviewed and certified by VASS Engineers locally who unequivocally confirm the design and materials chosen to manufacture the Blackhawk arms by long term suspension manufacturer Roadsafe Automotive products, and that they are of sound design and furthermore exceed the original equipment by design in strength and functionality.

A key feature identified by the FEA testing was the amount of deflection seen between the OE component and the Blackhawk UCA, with the Blackhawk arms being 3 times stiffer than the original equipment, resulting in significant increased handling and feel of your vehicle as the suspension cycles.

The manufacturing process is controlled by Roadsafe with a range of Quality Assurance procedures in place, some of these include…

- Welding specifications, Material & procedure

- Material selection

- Manufacturing jigs inspected for conformity regularly

- Random post manufacturing QC checks

- ISO/TS16949:2009

- IATF number 0224504 – Manufacture of steering and suspension parts

Based on years of experience in manufacturing a large volume of suspension components, Roadsafe is able to ensure the manufacturing process is of standard delivering a high quality component to market.

Spare Parts are available for our entire product range!

Ball Joint Part Number: BJ3841HD

Bushing Part Number: S0525R

Ball Joint Cap Part Number: UCABHCAP2

- Reduced caster correction – causing vague steering and response

- Bump steer resulting in reduced handling – with an out of control feeling

- Clearance issues to suspension & wheels/tyres – larger wheels can hit suspension components

- Some standard vehicles can have an issue of the UCA hitting the coil on full droop,

- Strength of OE equipment in offroad scenarios –

- Fixed Caster correction, we’ve identified the correct amount of caster correction required for lifts ranging from 30-70mm, by providing a bulk – fixed amount of caster, this offers the ability to utilise the factory adjustment to fine tune the caster required for your vehicles lift, with the UCA not being the limiting factor for increased droop relative to the other components.

- Camber change to meet OE spec, if your application requires increased camber, we can offer offset bushings to provide more camber.

- Clearance to larger aftermarket wheels & tyres – we often see larger than standard size tyres with wheel offsets having clearance issues to the OE UCA, our Blackhawk UCA’s minimise this as much as possible.

- Clearance to suspension components & chassis – a large number of OE UCA’s hit the coil or the chassis mounts on during the suspension travel limiting the amount of travel you can achieve, with revised bends and clearances identified the Blackhawk UCA’s will not contact the strut or the chassis limiting travel unless specifically designed to do so.

- Fixed position balljoint – Blackhawk UCA’s do not use an adjustable balljoint, with a fixed location balljoint we are able to offer OE specification for the ball joint itself.

- The position of the balljoint housings have been rotated to ensure the balljoint is not the limiting factor with maximum down travel. Roadsafe specifically chose a fixed ball joint for a number of reasons – in offroad applications the ball joint receives a large amount of “bump” loads, which over time can either knock an adjustable ball joint out of position leading to increased tyre wear due to a change in caster. Changing from a fixed balljoint mount reduces the structural integrity of the mount and the mounting platform of the balljoint, with any remote traveling we need to ensure strength and reliability is not compromised.

- There will never be a need to adjust or re-adjust your caster once established with the Blackhawk arms as the balljoint cannot be knocked out of position.

- Maintain OE specification ball joint & bushings – regardless of where you may go, if you need to replace a balljoint or bushing you can use genuine replacement parts or aftermarket OE specification replacement items, regardless of how remote you are at home or abroad.

- Ball joint binding – Often we see the ball joint limiting the amount of down travel because the OE ball stud hits the side of the ball joint housing, this creates a stress point on the ball stud creating an environment for potential terminal failure of the ball joint, it also limits the amount of down travel possible when used in conjunction with aftermarket suspension and longer shock lengths.

- Securing ABS lines – we incorporate tabs and mounts where practical so the OE lines can be secured discreetly where possible, reducing the potential of sticks and other debris from damaging the sensitive lines.

- Increased strength compared to the OE design – The design of the Blackhawk arms have shown with the use of FEA to be much stiffer than the OE arms, providing the driver with increased handling and response when the Blackhawk arms are fitted when compared to the OE arms, this is illustrated by the amount of deflection the FEA results have provided, with 3 times less deflection in the Blackhawk UCA’s.

- Heavy Duty Long life Balljoints – Roadsafe 4wd specially redesigned the OE balljoint into a heavy duty application, due to the nature of the application the 4wding community require a serviceable component, so we have a balljoint that is manufactured in the “hard to hard” style with a locating nylon disc that the ball stud terminates against, grease is pumped into the assembly through the top keeping everything lubricated and keeping any potential contaminants out of the boot region. The ball studs and seat area of the housing are all heat treated forming a hardened surface with the purpose of long life and limited wear.

- Dust Cap – Blackhawk arms that utilise a press in balljoint feature a machined alloy dust cap which is anodized black with engraved Blackhawk logo to deter corrosion etc, as a result creating a sealed housing to remove the balljoint from the elements such as water, dust & mud ensuring they are in the best possible environment.

- Finish – All arms are sand blasted upon completion and E coated black for a durable discreet finish, E coating is the same process the vehicles manufacturer used for the original equipment you are replacing.

- Welding specifications, Material & procedure

- Material selection

- Manufacturing jigs inspected for conformity regularly

- Random post manufacturing QC checks

- ISO/TS16949:2009

- IATF number 0224504 – Manufacture of steering and suspension parts

- Reduced caster correction – causing vague steering and response

- Bump steer resulting in reduced handling – with an out of control feeling

- Clearance issues to suspension & wheels/tyres – larger wheels can hit suspension components

- Some standard vehicles can have an issue of the UCA hitting the coil on full droop,

- Strength of OE equipment in offroad scenarios –

- Fixed Caster correction, we’ve identified the correct amount of caster correction required for lifts ranging from 30-70mm, by providing a bulk – fixed amount of caster, this offers the ability to utilise the factory adjustment to fine tune the caster required for your vehicles lift, with the UCA not being the limiting factor for increased droop relative to the other components.

- Camber change to meet OE spec, if your application requires increased camber, we can offer offset bushings to provide more camber.

- Clearance to larger aftermarket wheels & tyres – we often see larger than standard size tyres with wheel offsets having clearance issues to the OE UCA, our Blackhawk UCA’s minimise this as much as possible.

- Clearance to suspension components & chassis – a large number of OE UCA’s hit the coil or the chassis mounts on during the suspension travel limiting the amount of travel you can achieve, with revised bends and clearances identified the Blackhawk UCA’s will not contact the strut or the chassis limiting travel unless specifically designed to do so.

- Fixed position balljoint – Blackhawk UCA’s do not use an adjustable balljoint, with a fixed location balljoint we are able to offer OE specification for the ball joint itself.

- The position of the balljoint housings have been rotated to ensure the balljoint is not the limiting factor with maximum down travel. Roadsafe specifically chose a fixed ball joint for a number of reasons – in offroad applications the ball joint receives a large amount of “bump” loads, which over time can either knock an adjustable ball joint out of position leading to increased tyre wear due to a change in caster. Changing from a fixed balljoint mount reduces the structural integrity of the mount and the mounting platform of the balljoint, with any remote traveling we need to ensure strength and reliability is not compromised.

- There will never be a need to adjust or re-adjust your caster once established with the Blackhawk arms as the balljoint cannot be knocked out of position.

- Maintain OE specification ball joint & bushings – regardless of where you may go, if you need to replace a balljoint or bushing you can use genuine replacement parts or aftermarket OE specification replacement items, regardless of how remote you are at home or abroad.

- Ball joint binding – Often we see the ball joint limiting the amount of down travel because the OE ball stud hits the side of the ball joint housing, this creates a stress point on the ball stud creating an environment for potential terminal failure of the ball joint, it also limits the amount of down travel possible when used in conjunction with aftermarket suspension and longer shock lengths.

- Securing ABS lines – we incorporate tabs and mounts where practical so the OE lines can be secured discreetly where possible, reducing the potential of sticks and other debris from damaging the sensitive lines.

- Increased strength compared to the OE design – The design of the Blackhawk arms have shown with the use of FEA to be much stiffer than the OE arms, providing the driver with increased handling and response when the Blackhawk arms are fitted when compared to the OE arms, this is illustrated by the amount of deflection the FEA results have provided, with 3 times less deflection in the Blackhawk UCA’s.

- Heavy Duty Long life Balljoints – Roadsafe 4wd specially redesigned the OE balljoint into a heavy duty application, due to the nature of the application the 4wding community require a serviceable component, so we have a balljoint that is manufactured in the “hard to hard” style with a locating nylon disc that the ball stud terminates against, grease is pumped into the assembly through the top keeping everything lubricated and keeping any potential contaminants out of the boot region. The ball studs and seat area of the housing are all heat treated forming a hardened surface with the purpose of long life and limited wear.

- Dust Cap – Blackhawk arms that utilise a press in balljoint feature a machined alloy dust cap which is anodized black with engraved Blackhawk logo to deter corrosion etc, as a result creating a sealed housing to remove the balljoint from the elements such as water, dust & mud ensuring they are in the best possible environment.

- Finish – All arms are sand blasted upon completion and E coated black for a durable discreet finish, E coating is the same process the vehicles manufacturer used for the original equipment you are replacing.

- Welding specifications, Material & procedure

- Material selection

- Manufacturing jigs inspected for conformity regularly

- Random post manufacturing QC checks

- ISO/TS16949:2009

- IATF number 0224504 – Manufacture of steering and suspension parts

- Reduced caster correction – causing vague steering and response

- Bump steer resulting in reduced handling – with an out of control feeling

- Clearance issues to suspension & wheels/tyres – larger wheels can hit suspension components

- Some standard vehicles can have an issue of the UCA hitting the coil on full droop,

- Strength of OE equipment in offroad scenarios –

- Fixed Caster correction, we’ve identified the correct amount of caster correction required for lifts ranging from 30-70mm, by providing a bulk – fixed amount of caster, this offers the ability to utilise the factory adjustment to fine tune the caster required for your vehicles lift, with the UCA not being the limiting factor for increased droop relative to the other components.

- Camber change to meet OE spec, if your application requires increased camber, we can offer offset bushings to provide more camber.

- Clearance to larger aftermarket wheels & tyres – we often see larger than standard size tyres with wheel offsets having clearance issues to the OE UCA, our Blackhawk UCA’s minimise this as much as possible.

- Clearance to suspension components & chassis – a large number of OE UCA’s hit the coil or the chassis mounts on during the suspension travel limiting the amount of travel you can achieve, with revised bends and clearances identified the Blackhawk UCA’s will not contact the strut or the chassis limiting travel unless specifically designed to do so.

- Fixed position balljoint – Blackhawk UCA’s do not use an adjustable balljoint, with a fixed location balljoint we are able to offer OE specification for the ball joint itself.

- The position of the balljoint housings have been rotated to ensure the balljoint is not the limiting factor with maximum down travel. Roadsafe specifically chose a fixed ball joint for a number of reasons – in offroad applications the ball joint receives a large amount of “bump” loads, which over time can either knock an adjustable ball joint out of position leading to increased tyre wear due to a change in caster. Changing from a fixed balljoint mount reduces the structural integrity of the mount and the mounting platform of the balljoint, with any remote traveling we need to ensure strength and reliability is not compromised.

- There will never be a need to adjust or re-adjust your caster once established with the Blackhawk arms as the balljoint cannot be knocked out of position.

- Maintain OE specification ball joint & bushings – regardless of where you may go, if you need to replace a balljoint or bushing you can use genuine replacement parts or aftermarket OE specification replacement items, regardless of how remote you are at home or abroad.

- Ball joint binding – Often we see the ball joint limiting the amount of down travel because the OE ball stud hits the side of the ball joint housing, this creates a stress point on the ball stud creating an environment for potential terminal failure of the ball joint, it also limits the amount of down travel possible when used in conjunction with aftermarket suspension and longer shock lengths.

- Securing ABS lines – we incorporate tabs and mounts where practical so the OE lines can be secured discreetly where possible, reducing the potential of sticks and other debris from damaging the sensitive lines.

- Increased strength compared to the OE design – The design of the Blackhawk arms have shown with the use of FEA to be much stiffer than the OE arms, providing the driver with increased handling and response when the Blackhawk arms are fitted when compared to the OE arms, this is illustrated by the amount of deflection the FEA results have provided, with 3 times less deflection in the Blackhawk UCA’s.

- Heavy Duty Long life Balljoints – Roadsafe 4wd specially redesigned the OE balljoint into a heavy duty application, due to the nature of the application the 4wding community require a serviceable component, so we have a balljoint that is manufactured in the “hard to hard” style with a locating nylon disc that the ball stud terminates against, grease is pumped into the assembly through the top keeping everything lubricated and keeping any potential contaminants out of the boot region. The ball studs and seat area of the housing are all heat treated forming a hardened surface with the purpose of long life and limited wear.

- Dust Cap – Blackhawk arms that utilise a press in balljoint feature a machined alloy dust cap which is anodized black with engraved Blackhawk logo to deter corrosion etc, as a result creating a sealed housing to remove the balljoint from the elements such as water, dust & mud ensuring they are in the best possible environment.

- Finish – All arms are sand blasted upon completion and E coated black for a durable discreet finish, E coating is the same process the vehicles manufacturer used for the original equipment you are replacing.

- Welding specifications, Material & procedure

- Material selection

- Manufacturing jigs inspected for conformity regularly

- Random post manufacturing QC checks

- ISO/TS16949:2009

- IATF number 0224504 – Manufacture of steering and suspension parts

- Reduced caster correction – causing vague steering and response

- Bump steer resulting in reduced handling – with an out of control feeling

- Clearance issues to suspension & wheels/tyres – larger wheels can hit suspension components

- Some standard vehicles can have an issue of the UCA hitting the coil on full droop,

- Strength of OE equipment in offroad scenarios –

- Fixed Caster correction, we’ve identified the correct amount of caster correction required for lifts ranging from 30-70mm, by providing a bulk – fixed amount of caster, this offers the ability to utilise the factory adjustment to fine tune the caster required for your vehicles lift, with the UCA not being the limiting factor for increased droop relative to the other components.

- Camber change to meet OE spec, if your application requires increased camber, we can offer offset bushings to provide more camber.

- Clearance to larger aftermarket wheels & tyres – we often see larger than standard size tyres with wheel offsets having clearance issues to the OE UCA, our Blackhawk UCA’s minimise this as much as possible.

- Clearance to suspension components & chassis – a large number of OE UCA’s hit the coil or the chassis mounts on during the suspension travel limiting the amount of travel you can achieve, with revised bends and clearances identified the Blackhawk UCA’s will not contact the strut or the chassis limiting travel unless specifically designed to do so.

- Fixed position balljoint – Blackhawk UCA’s do not use an adjustable balljoint, with a fixed location balljoint we are able to offer OE specification for the ball joint itself.

- The position of the balljoint housings have been rotated to ensure the balljoint is not the limiting factor with maximum down travel. Roadsafe specifically chose a fixed ball joint for a number of reasons – in offroad applications the ball joint receives a large amount of “bump” loads, which over time can either knock an adjustable ball joint out of position leading to increased tyre wear due to a change in caster. Changing from a fixed balljoint mount reduces the structural integrity of the mount and the mounting platform of the balljoint, with any remote traveling we need to ensure strength and reliability is not compromised.

- There will never be a need to adjust or re-adjust your caster once established with the Blackhawk arms as the balljoint cannot be knocked out of position.

- Maintain OE specification ball joint & bushings – regardless of where you may go, if you need to replace a balljoint or bushing you can use genuine replacement parts or aftermarket OE specification replacement items, regardless of how remote you are at home or abroad.

- Ball joint binding – Often we see the ball joint limiting the amount of down travel because the OE ball stud hits the side of the ball joint housing, this creates a stress point on the ball stud creating an environment for potential terminal failure of the ball joint, it also limits the amount of down travel possible when used in conjunction with aftermarket suspension and longer shock lengths.

- Securing ABS lines – we incorporate tabs and mounts where practical so the OE lines can be secured discreetly where possible, reducing the potential of sticks and other debris from damaging the sensitive lines.

- Increased strength compared to the OE design – The design of the Blackhawk arms have shown with the use of FEA to be much stiffer than the OE arms, providing the driver with increased handling and response when the Blackhawk arms are fitted when compared to the OE arms, this is illustrated by the amount of deflection the FEA results have provided, with 3 times less deflection in the Blackhawk UCA’s.

- Heavy Duty Long life Balljoints – Roadsafe 4wd specially redesigned the OE balljoint into a heavy duty application, due to the nature of the application the 4wding community require a serviceable component, so we have a balljoint that is manufactured in the “hard to hard” style with a locating nylon disc that the ball stud terminates against, grease is pumped into the assembly through the top keeping everything lubricated and keeping any potential contaminants out of the boot region. The ball studs and seat area of the housing are all heat treated forming a hardened surface with the purpose of long life and limited wear.

- Dust Cap – Blackhawk arms that utilise a press in balljoint feature a machined alloy dust cap which is anodized black with engraved Blackhawk logo to deter corrosion etc, as a result creating a sealed housing to remove the balljoint from the elements such as water, dust & mud ensuring they are in the best possible environment.

- Finish – All arms are sand blasted upon completion and E coated black for a durable discreet finish, E coating is the same process the vehicles manufacturer used for the original equipment you are replacing.

- Welding specifications, Material & procedure

- Material selection

- Manufacturing jigs inspected for conformity regularly

- Random post manufacturing QC checks

- ISO/TS16949:2009

- IATF number 0224504 – Manufacture of steering and suspension parts

- Reduced caster correction – causing vague steering and response

- Bump steer resulting in reduced handling – with an out of control feeling

- Clearance issues to suspension & wheels/tyres – larger wheels can hit suspension components

- Some standard vehicles can have an issue of the UCA hitting the coil on full droop,

- Strength of OE equipment in offroad scenarios –

- Fixed Caster correction, we’ve identified the correct amount of caster correction required for lifts ranging from 30-70mm, by providing a bulk – fixed amount of caster, this offers the ability to utilise the factory adjustment to fine tune the caster required for your vehicles lift, with the UCA not being the limiting factor for increased droop relative to the other components.

- Camber change to meet OE spec, if your application requires increased camber, we can offer offset bushings to provide more camber.

- Clearance to larger aftermarket wheels & tyres – we often see larger than standard size tyres with wheel offsets having clearance issues to the OE UCA, our Blackhawk UCA’s minimise this as much as possible.

- Clearance to suspension components & chassis – a large number of OE UCA’s hit the coil or the chassis mounts on during the suspension travel limiting the amount of travel you can achieve, with revised bends and clearances identified the Blackhawk UCA’s will not contact the strut or the chassis limiting travel unless specifically designed to do so.

- Fixed position balljoint – Blackhawk UCA’s do not use an adjustable balljoint, with a fixed location balljoint we are able to offer OE specification for the ball joint itself.

- The position of the balljoint housings have been rotated to ensure the balljoint is not the limiting factor with maximum down travel. Roadsafe specifically chose a fixed ball joint for a number of reasons – in offroad applications the ball joint receives a large amount of “bump” loads, which over time can either knock an adjustable ball joint out of position leading to increased tyre wear due to a change in caster. Changing from a fixed balljoint mount reduces the structural integrity of the mount and the mounting platform of the balljoint, with any remote traveling we need to ensure strength and reliability is not compromised.

- There will never be a need to adjust or re-adjust your caster once established with the Blackhawk arms as the balljoint cannot be knocked out of position.

- Maintain OE specification ball joint & bushings – regardless of where you may go, if you need to replace a balljoint or bushing you can use genuine replacement parts or aftermarket OE specification replacement items, regardless of how remote you are at home or abroad.

- Ball joint binding – Often we see the ball joint limiting the amount of down travel because the OE ball stud hits the side of the ball joint housing, this creates a stress point on the ball stud creating an environment for potential terminal failure of the ball joint, it also limits the amount of down travel possible when used in conjunction with aftermarket suspension and longer shock lengths.

- Securing ABS lines – we incorporate tabs and mounts where practical so the OE lines can be secured discreetly where possible, reducing the potential of sticks and other debris from damaging the sensitive lines.

- Increased strength compared to the OE design – The design of the Blackhawk arms have shown with the use of FEA to be much stiffer than the OE arms, providing the driver with increased handling and response when the Blackhawk arms are fitted when compared to the OE arms, this is illustrated by the amount of deflection the FEA results have provided, with 3 times less deflection in the Blackhawk UCA’s.

- Heavy Duty Long life Balljoints – Roadsafe 4wd specially redesigned the OE balljoint into a heavy duty application, due to the nature of the application the 4wding community require a serviceable component, so we have a balljoint that is manufactured in the “hard to hard” style with a locating nylon disc that the ball stud terminates against, grease is pumped into the assembly through the top keeping everything lubricated and keeping any potential contaminants out of the boot region. The ball studs and seat area of the housing are all heat treated forming a hardened surface with the purpose of long life and limited wear.

- Dust Cap – Blackhawk arms that utilise a press in balljoint feature a machined alloy dust cap which is anodized black with engraved Blackhawk logo to deter corrosion etc, as a result creating a sealed housing to remove the balljoint from the elements such as water, dust & mud ensuring they are in the best possible environment.

- Finish – All arms are sand blasted upon completion and E coated black for a durable discreet finish, E coating is the same process the vehicles manufacturer used for the original equipment you are replacing.

- Welding specifications, Material & procedure

- Material selection

- Manufacturing jigs inspected for conformity regularly

- Random post manufacturing QC checks

- ISO/TS16949:2009

- IATF number 0224504 – Manufacture of steering and suspension parts

- It has been identified some Spanish models only have 1 camber adjusting bolt on the front lower control arm. The Blackhawk UCA’s will not suit these vehicles due to their limited scope for alignment.

- Reduced caster correction – causing vague steering and response

- Bump steer resulting in reduced handling – with an out of control feeling

- Clearance issues to suspension & wheels/tyres – larger wheels can hit suspension components

- Some standard vehicles can have an issue of the UCA hitting the coil on full droop,

- Strength of OE equipment in offroad scenarios –

- Fixed Caster correction, we’ve identified the correct amount of caster correction required for lifts ranging from 30-70mm, by providing a bulk – fixed amount of caster, this offers the ability to utilise the factory adjustment to fine tune the caster required for your vehicles lift, with the UCA not being the limiting factor for increased droop relative to the other components.

- Camber change to meet OE spec, if your application requires increased camber, we can offer offset bushings to provide more camber.

- Clearance to larger aftermarket wheels & tyres – we often see larger than standard size tyres with wheel offsets having clearance issues to the OE UCA, our Blackhawk UCA’s minimise this as much as possible.

- Clearance to suspension components & chassis – a large number of OE UCA’s hit the coil or the chassis mounts on during the suspension travel limiting the amount of travel you can achieve, with revised bends and clearances identified the Blackhawk UCA’s will not contact the strut or the chassis limiting travel unless specifically designed to do so.

- Fixed position balljoint – Blackhawk UCA’s do not use an adjustable balljoint, with a fixed location balljoint we are able to offer OE specification for the ball joint itself.

- The position of the balljoint housings have been rotated to ensure the balljoint is not the limiting factor with maximum down travel. Roadsafe specifically chose a fixed ball joint for a number of reasons – in offroad applications the ball joint receives a large amount of “bump” loads, which over time can either knock an adjustable ball joint out of position leading to increased tyre wear due to a change in caster. Changing from a fixed balljoint mount reduces the structural integrity of the mount and the mounting platform of the balljoint, with any remote traveling we need to ensure strength and reliability is not compromised.

- There will never be a need to adjust or re-adjust your caster once established with the Blackhawk arms as the balljoint cannot be knocked out of position.

- Maintain OE specification ball joint & bushings – regardless of where you may go, if you need to replace a balljoint or bushing you can use genuine replacement parts or aftermarket OE specification replacement items, regardless of how remote you are at home or abroad.

- Ball joint binding – Often we see the ball joint limiting the amount of down travel because the OE ball stud hits the side of the ball joint housing, this creates a stress point on the ball stud creating an environment for potential terminal failure of the ball joint, it also limits the amount of down travel possible when used in conjunction with aftermarket suspension and longer shock lengths.

- Securing ABS lines – we incorporate tabs and mounts where practical so the OE lines can be secured discreetly where possible, reducing the potential of sticks and other debris from damaging the sensitive lines.

- Increased strength compared to the OE design – The design of the Blackhawk arms have shown with the use of FEA to be much stiffer than the OE arms, providing the driver with increased handling and response when the Blackhawk arms are fitted when compared to the OE arms, this is illustrated by the amount of deflection the FEA results have provided, with 3 times less deflection in the Blackhawk UCA’s.

- Heavy Duty Long life Balljoints – Roadsafe 4wd specially redesigned the OE balljoint into a heavy duty application, due to the nature of the application the 4wding community require a serviceable component, so we have a balljoint that is manufactured in the “hard to hard” style with a locating nylon disc that the ball stud terminates against, grease is pumped into the assembly through the top keeping everything lubricated and keeping any potential contaminants out of the boot region. The ball studs and seat area of the housing are all heat treated forming a hardened surface with the purpose of long life and limited wear.

- Dust Cap – Blackhawk arms that utilise a press in balljoint feature a machined alloy dust cap which is anodized black with engraved Blackhawk logo to deter corrosion etc, as a result creating a sealed housing to remove the balljoint from the elements such as water, dust & mud ensuring they are in the best possible environment.

- Finish – All arms are sand blasted upon completion and E coated black for a durable discreet finish, E coating is the same process the vehicles manufacturer used for the original equipment you are replacing.

- Welding specifications, Material & procedure

- Material selection

- Manufacturing jigs inspected for conformity regularly

- Random post manufacturing QC checks

- ISO/TS16949:2009

- IATF number 0224504 – Manufacture of steering and suspension parts

- Reduced caster correction – causing vague steering and response

- Bump steer resulting in reduced handling – with an out of control feeling

- Clearance issues to suspension & wheels/tyres – larger wheels can hit suspension components

- Some standard vehicles can have an issue of the UCA hitting the coil on full droop,

- Strength of OE equipment in offroad scenarios –

- Fixed Caster correction, we’ve identified the correct amount of caster correction required for lifts ranging from 30-70mm, by providing a bulk – fixed amount of caster, this offers the ability to utilise the factory adjustment to fine tune the caster required for your vehicles lift, with the UCA not being the limiting factor for increased droop relative to the other components.

- Camber change to meet OE spec, if your application requires increased camber, we can offer offset bushings to provide more camber.

- Clearance to larger aftermarket wheels & tyres – we often see larger than standard size tyres with wheel offsets having clearance issues to the OE UCA, our Blackhawk UCA’s minimise this as much as possible.

- Clearance to suspension components & chassis – a large number of OE UCA’s hit the coil or the chassis mounts on during the suspension travel limiting the amount of travel you can achieve, with revised bends and clearances identified the Blackhawk UCA’s will not contact the strut or the chassis limiting travel unless specifically designed to do so.

- Fixed position balljoint – Blackhawk UCA’s do not use an adjustable balljoint, with a fixed location balljoint we are able to offer OE specification for the ball joint itself.

- The position of the balljoint housings have been rotated to ensure the balljoint is not the limiting factor with maximum down travel. Roadsafe specifically chose a fixed ball joint for a number of reasons – in offroad applications the ball joint receives a large amount of “bump” loads, which over time can either knock an adjustable ball joint out of position leading to increased tyre wear due to a change in caster. Changing from a fixed balljoint mount reduces the structural integrity of the mount and the mounting platform of the balljoint, with any remote traveling we need to ensure strength and reliability is not compromised.